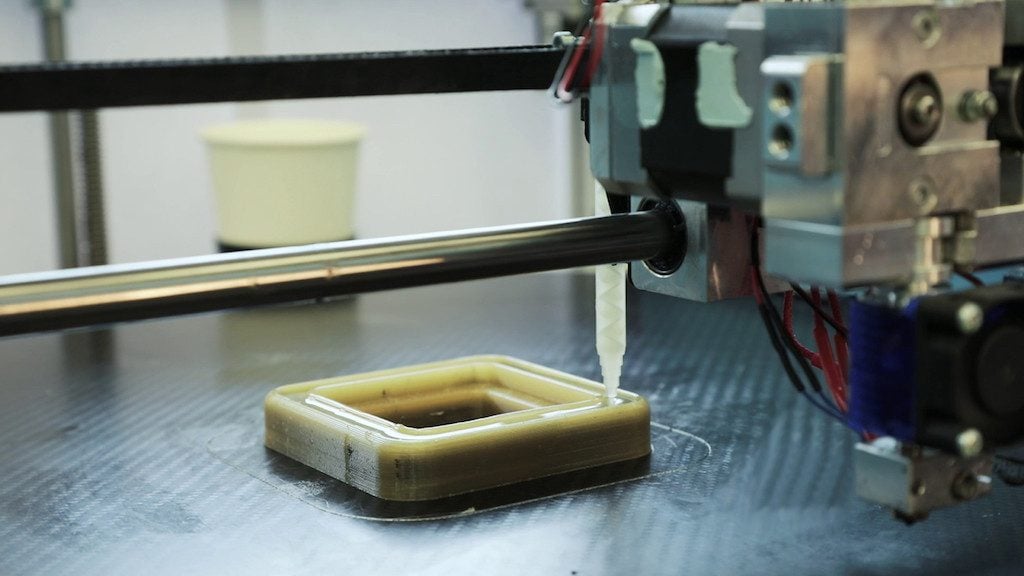

The alcohol evaporates, and the resin is left behind. Parts washed in this IPA get coated with a thin layer of diluted resin. The more parts are washed in a quantity of IPA, the higher the concentration of resin in the IPA becomes. This happens in one or both of the following ways: If enough uncured (or partly-cured) resin is left behind after part washing, it contaminates a print’s surface and makes it sticky. Just as with hands, incomplete washing is asking for trouble. Uncured resin progressively contaminates the IPA used to wash parts, and it clings to some spots on a model more than others. Ideally this process results in a perfectly clean part, but this is not always the case. Some resins get additional curing time by placing them in a UV cure box (or in a pinch, left in sunlight.) This excess resin needs to be rinsed away with a solvent, usually isopropyl alcohol (IPA). The result of this process is a solid object with no distinct layers that is also covered in uncured resin from the build tank. Each subsequent layer bonds with the previous one, and the UV hardens not just the current layer, but also further cures previous ones as the UV penetrates into the model. This gives the next layer something to bond to. Some of the resin in a layer remains in what is called a green state, which can be thought of as solid but not fully cured. But this curing process is not always driven to absolute completion. In the SLA process, objects are created one slice at a time, and each slice is a thin layer of resin selectively exposed to UV so that it becomes hard. It happens in degrees, and taking advantage of this is indeed part of how SLA printers operate. But this process is not a perfectly binary one where all exposed resin becomes completely solid, while unexposed resin remains equally and totally liquid. The resin used in stereolithography (SLA) is a syrupy liquid that is UV-cured, meaning it hardens when exposed to the right wavelength of light. We’ll get into those more extreme procedures shortly, but first let’s understand a bit more about how resin works, then look at how that applies to preventing and removing tacky surfaces on finished prints.

If the part remains sticky after it is dry, more aggressive steps can be taken. The best thing to do with a sticky print is to immediately re-wash it in clean isopropyl alcohol (IPA) before the UV present in ambient light cures stray resin. Giving the model some extra ultraviolet (UV) curing seems like it should fix the problem, but it probably does not.

We are confused and think it is an error (On device B) someone else has actually changed the task work on device B.After going through all the trouble of printing a part in resin, discovering it feels sticky or tacky to the touch is pretty unwelcome. For example, the task work is "automatically" updated to an unexpected value.

0 kommentar(er)

0 kommentar(er)